-

Development of an Electric Vehicle Engineering Technology Program for the Middle and East Tennessee Regions

Electric Vehicle Train-the-Trainer Workshop coming soon

Project Summary:

Overview:

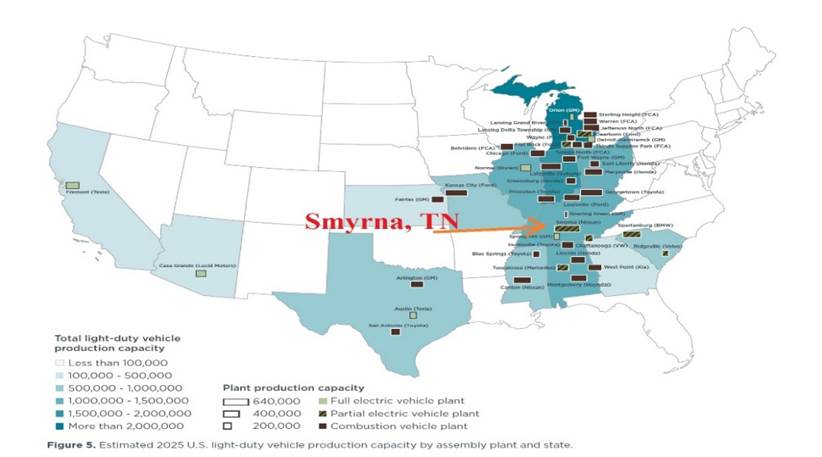

the State of Tennessee ranks fourth on the U.S. in number of automobile manufacturing jobs after Michigan, Illinois, and Ohio according to the United States Bureau of Labor Statistics, with approximately 20,000 jobs in auto manufacturing in 2023.

In addition to that, Tennessee ranks the first state in the southeast in Electric Vehicle Manufacturing, employment, and investment. The Tennessee Department of Economic and Community Development (TN-ECD) states that over $16.2 billion in capital investment in electric vehicle projects have been made in Tennessee since 2017.

However, this growth is accompanied by a critical shortage in the workforce, several think-tanks predict a critical shortage of electric vehicle technicians in 2030 with too few technicians to service the volume of electric-powered vehicles. Thus, the need for electric vehicle technicians is expected to grow rapidly in the coming years as more people switch to electric vehicles. Another research study by McKinsey & Company found that 60% of automotive executives believe that the shortage of qualified technicians is a major challenge for the industry, and negatively impacts the industry’s ability to innovate and grow.

In this project, we seek to address this shortage in the skilled workforce by creating an Electric Vehicle Engineering Technology program at Motlow State Community College that serves the Middle Tennessee region, and to add a technical certificate in the program recently launched at Chattanooga State Community College, which serves the East Tennessee region. The programs will provide students with the skills and knowledge they need to work on electric vehicles. This will also help in ensuring that the electric vehicle industry has a workforce pool that is qualified to maintain and repair electric vehicles safely and efficiently

Intellectual Merit:

Throughout this project, the following goals will be achieved: 1) To Prepare the workforce for the upcoming demand for electric vehicle technicians: this will be accomplished by developing an Electric Vehicle Engineering Technology program at Motlow State Community College, and developing a certificate in EV battery technology at Chattanooga State, and developing train-the-trainer workshops to train faculty of other community colleges on the EV technology. 2) Increasing Public Awareness of the electric vehicle technology and components and 3) Increase Presence of Women and other Under-Represented Groups in Advanced Manufacturing:

Broader Impacts:

Economic Impact: As a result of this project, an electric vehicle technology program will be created in Motlow State Community College and a technical certificate battery management will be developed at Chattanooga State. Students will be trained to handle all-electric vehicles, and will fill in the gap that is expected to take place in the coming years. This project will effectively help improve the economy in the regions through the high demand skill training. Industrial Impact: This project will provide the automotive industry with a skilled workforce that is trained to handle the electric vehicle technology. Impact on improving Diversity, Equity, and Inclusion in manufacturing: The project has a strong presence of women and PI’s from different backgrounds that play core roles in the project. This diverse team is important to ensure equitable access for students from all backgrounds and give a feeling of inclusiveness for potential students to register in this new program. In addition to that, outreach activities will be made by the project team in the economically-disadvantaged regions in Tennessee and for the women in engineering.

History of Electric Vehicles

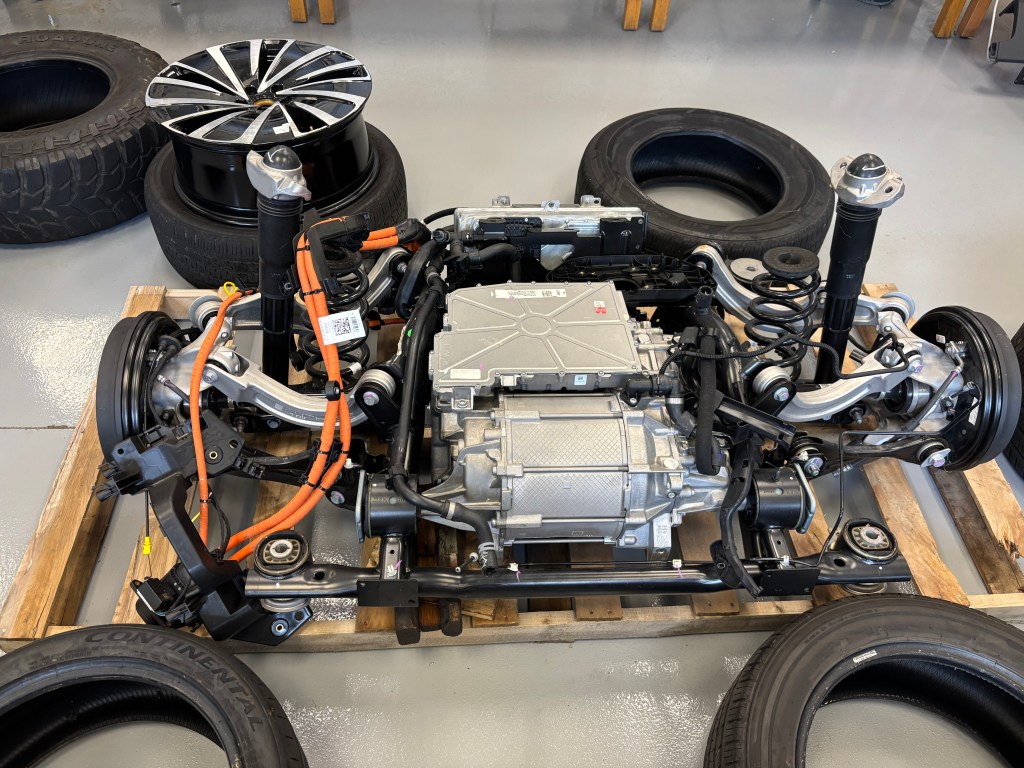

All-electric vehicles, also referred to as battery electric vehicles (BEVs), are powered by electric motors instead of an internal combustion engine. These vehicles use battery packs to power the electric motor and must be plugged in to a wall outlet or charging equipment, also referred to as electric vehicle supply equipment (EVSE). Because it runs on electricity, the vehicle emits no exhaust from a tailpipe and does not contain the typical liquid fuel components, such as a fuel pump, fuel line, or fuel tank.

The first all-electric vehicles hit the roads in the early 1900’s, and started to be mass produced in 1902. However, they faced the primary challenge of lack of sufficient energy storage, which limited their range to a few tens of miles. After the Form Motors Company was able to mass produce combustion-engine vehicles in its first automated assembly line, the all-electric vehicles quickly declined.

Figure 1. One of the earliest models of all-electric vehicles (1909) Left. Mass production of the combustion engine vehicles in the first automated assembly line by the Ford Motor Company in 1913 (Right) caused the fast decline of the early electric vehicles.

Primary Components:

- DC/DC converter: This device converts higher-voltage DC power from the traction battery pack to the lower-voltage DC power needed to run vehicle accessories and recharge the auxiliary battery.

- Electric traction motor: Using power from the traction battery pack, this motor drives the vehicle’s wheels. Some vehicles use motor generators that perform both the drive and regeneration functions.

- Onboard charger: Takes the incoming AC electricity supplied via the charge port and converts it to DC power for charging the traction battery. It also communicates with the charging equipment and monitors battery characteristics such as voltage, current, temperature, and state of charge while charging the pack.

- Power electronics controller: This unit manages the flow of electrical energy delivered by the traction battery, controlling the speed of the electric traction motor and the torque it produces.

- Thermal Cooling system: This system maintains a proper operating temperature range of the engine, electric motor, power electronics, and other components.

- Traction battery pack: Stores electricity for use by the electric traction motor.

- Transmission System: The transmission transfers mechanical power from the electric traction motor to drive the wheels.

- Auxiliary Battery: In an electric drive vehicle, the auxiliary battery provides electricity to power vehicle accessories.

- Charge port: The charge port allows the vehicle to connect to an external power supply in order to charge the traction battery pack.

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.